Through-Hole Assembly Experts

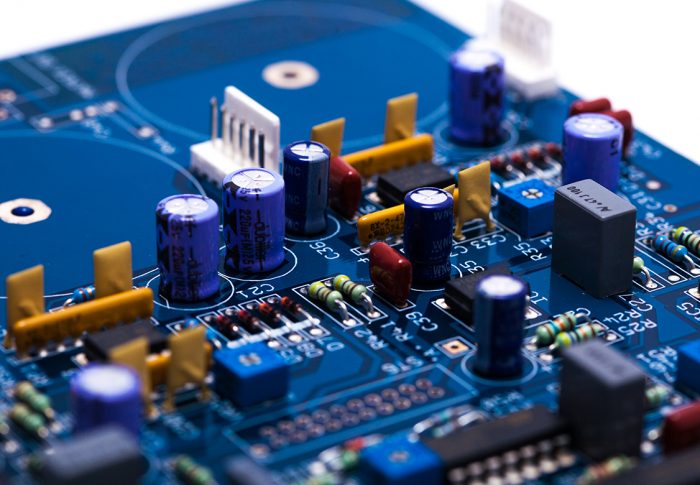

Components used in through-hole assembly (also known as conventional assembly) have legs which are passed through the PCB and then soldered in place.

This creates both electrical and mechanical connections. Applications include products and equipment that require heavy-duty components, such as power supplies.

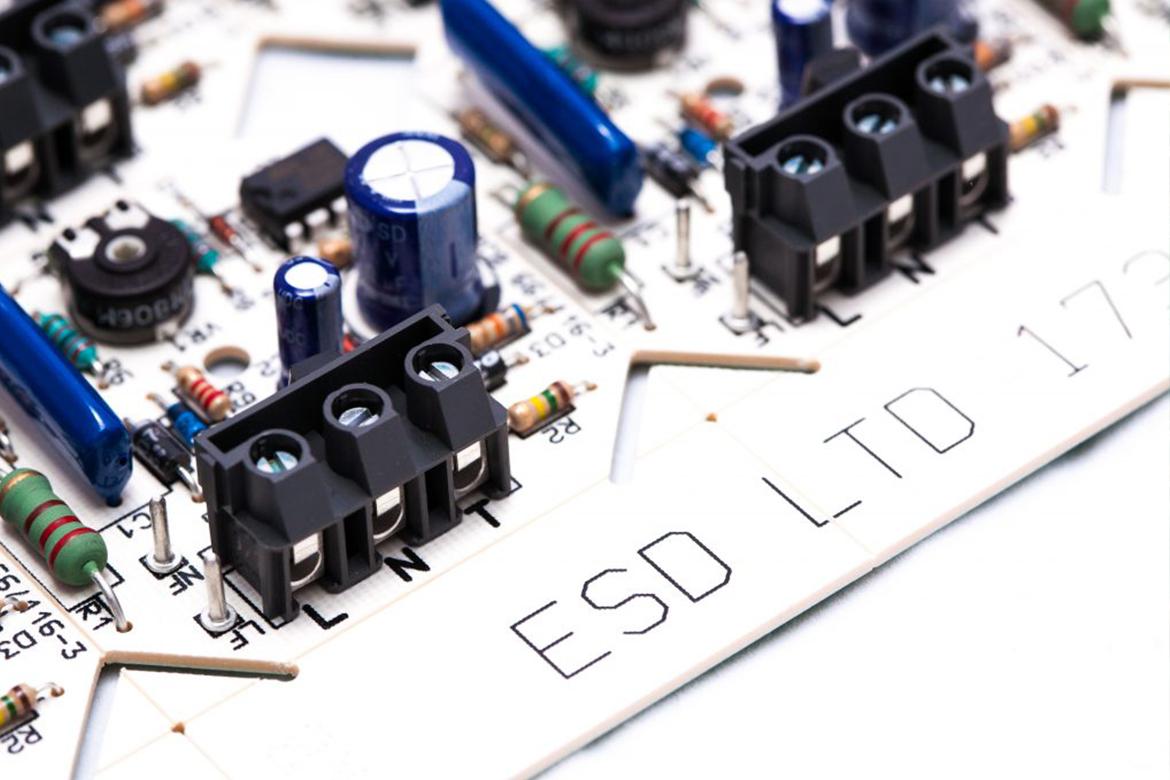

At ESD we regularly use our automatic insertion machines to give customers a fast turnaround compared to hand assembly alone. Our automated assembly equipment has a pitch range of 2.5 to 5.0mm. We use our flow-solder machine for a quick, quality turnaround.

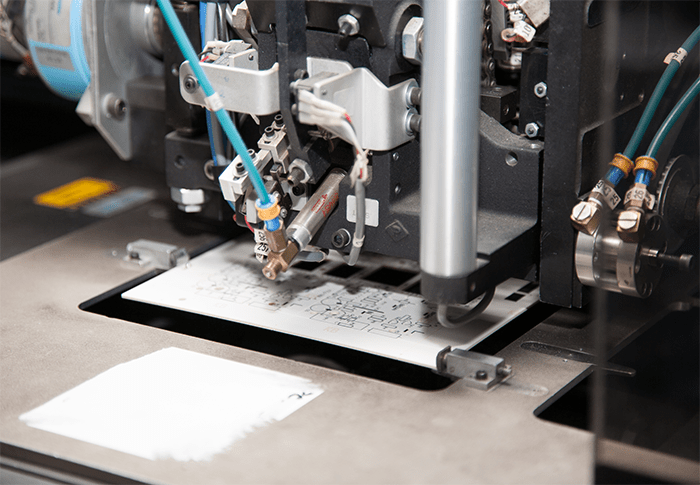

How does Automated Insertion work?

Our operator loads the production-ready components into the machine and selects the right program. He loads the PCB onto a carrier that moves and rotates the PCB for each component insertion.

The carrier presents the required PCB component location to the machine ‘head’. The head grips the selected component and cuts the legs from the carrier tape. It slots the component into the board, and checks the component is there. The machine then bends the legs to secure the item in place.

When all of the programmed components have been fitted some hand assembly of other, bulkier components is often required.

If the assembly is suitable for flow soldering we put a mask over holes in the PCB to stop them filling with solder, in line with customer and process requirements. We then load it onto our flow solder machine. The internal conveyor carries the PCB through heaters, then over a wave of solder. This touches the underside of the PCB, filling the joint between the component legs and the PCB. The PCB then cools down, and the masking is removed.

Advantages of Automated Insertion

Street lighting, traffic lights, road signs, X-ray machines, mixing desks, weighing scales, pottery kilns, cleaning equipment, personal alarms, children’s rides and power supplies are some of the industries where you can find ESD produced through-hole assemblies.

- Higher speed assembly when compared to hand placement

- The detection of ejected parts

- Interference-free insertions

- Provides a strong mechanical connection with the pcb. This is especially useful in vibrating environments, or where the PCB may be flexed.

BUSINESS SECTORS WE DEAL IN

Here are examples of some of the industries and applications that you’ll find ESD products worldwide.